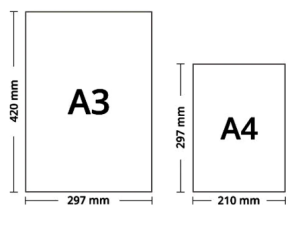

The purpose of this post is to explain in detail the steps and options available to place an order for printing of an A3 or A4 size document.

Before proceeding with your order kindly note the following:

All printing done using this service will have a 3 to 5mm white border margin on all sides of the page. Should you wish full bleed printing, that is printing to the edge of the paper so the final result has no margins please contact us and we will assist you. Our in-house design and print room specialists will be happy to assist you. We offer high quality poster printing, catalogue and brochure printing, flyers, business cards, greeting cards and many more printing options from our sister brand optima.mt.

Although we do give a quick overview to check that the file to be printed is in order, we do not aim to go through each page and question any doubtful content. For confidentiality purposes we do not read through the specific text and we do not check any sequence or referencing in the document.

Our printers are maintained to their optimum levels and we strive to ensure that the print is of the best quality. However please keep in mind that the colours and contrast visible on a monitor or a mobile device are different from that seen on a paper. The colour spectrum of a light-emitting screen is different from the colours used by printers to build a full colour print. Should you require very accurate colour matching please do not use this service but contact us and we will assist you through our in-house design and print room services at optima.mt.

Preparing an order for printing:

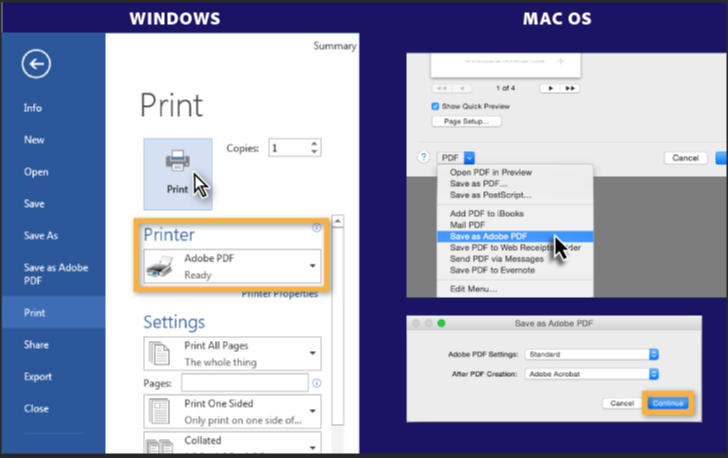

1. Choose the file to print. Only PDF files are accepted. If your document is in a different format such as Microsoft Word please go to File – Save As and choose PDF format. If the software does not allow this, you will normally have the option to export the file to PDF or you may go to File – Print and as a printer choose Microsoft Print to PDF or a PDF printer such as Adobe PDF

2. Once the file is uploaded the number of pages are automatically detected by our printing application. If you do not wish to print certain pages within the document we recommend that you edit the file, save as PDF and upload it again. Please use a different file name to ensure that the latest version of the file is uploaded.

3. Select the paper size – A3 or A4. If the document page size is different from the paper size chosen here, we will always print ‘fit to printing paper size’. If your page size is the same as the printing paper size we will print ‘actual size’.

4. Duplex Mode – Choose either one sided print or two sided print. Two sided printing is also known as back-to-back printing or duplex printing. This means that you will have one page printed on the front side of the paper and the next page on the back side of the paper. Portrait documents are always printed duplex from the long edge. If the file is set as landscape and you choose a binding finish we will print duplex from the long edge. Unless specified in the order note we will use our judgement to decide whether it is best to print from the long edge or the short edge. If duplex mode is selected printing can only be done in Black Only or Full Colour. Mixed Mode option is not available. Certain paper types do not support duplex printing.

5. Type of paper

The most common paper type is the 80gsm uncoated white paper. Other paper options available are:

100gsm or 120gsm Premium White Uncoated Paper – This paper is slightly thicker and smoother and provides a nicer finish than the 80gsm paper. This paper is used for presentation of reports or to print colourful images. It may also be used to give more body (increase the spine thickness) of a short report.

200gsm or 300gsm Uncoated White Paper, also referred to as card stock – The thickness is similar to that of the school/crafts cardboard – in Maltese referred to as Kartonċin. This card stock may be used to print pictures, learning cards, certificates or notices.

80gsm Ivory Coloured Paper (Dyslexia Friendly) – This paper is commonly used to aid students with learning difficulties. It is used as an alternative to the 80gsm white paper.

80gsm Coloured Paper – There are various colours to choose from and we recommend printing in black only on coloured paper. Dark colours are not included in our choice since the print will not be visible.

200gsm Uncoated Coloured Paper – There are various colours to choose from. The thickness is similar to that of the school/crafts cardboard – in Maltese referred to as Kartonċin. We recommend printing in black only on coloured paper. Dark colours are not included in our choice since the print will not be visible.

135gsm and 250gsm Coated White Paper (Silk Paper) – This paper has a silk smooth finish and is often referred to as semi matte paper. It may be used to print images or content that requires more brightness than the uncoated matte paper. We do not recommend using this paper type if you need to write on the printed document, unless using a quick dry writing instrument.

280gsm Certificate Paper (Yellow Sand Colour) – This paper finish is also referred to as Vellum paper. It has an egg shell look and feel. This style of paper appears to be smooth but has a subtle roughness making it a little rougher then smooth paper. As the name implies it is mostly used for certificate printing. Once printed it gives a rich look and feel to the document. Duplex printing is not supported for this paper type.

300gsm Linen Textured White paper – This paper looks and feels much like the linen fabrics in your home. It has a similar raised crosshatch pattern. The paper finish is also referred to as Embossed paper, consisting of a raised detailing that can be both seen and felt. Linen texture paper is frequently used to give an elegant look and depending on the artwork it can also give a vintage look to your print. Duplex printing is not supported for this paper type.

Transparency Sheets for Overhead Projectors – These sheets are transparent film that support laser printing in both black and colour and are commonly used with an overhead projector. These sheets are also used for creative crafts and DIY projects. Duplex printing is not supported for this paper type.

Paper Sticker – This is Self-Adhesive A4 Paper. It is suitable for indoor use. One may prepare the artwork on a normal A4 document and once printed it can be self trimmed to your required size. Pre-cut self-adhesive paper labels are also available from our website. This sticker may be used for internal temporary signage or to stick information labels to paper and other smooth surfaces.

Polyester Transparent/White Sticker (Waterproof) Sticker – This is a Self-Adhesive Polyester material and is therefore waterproof. This sticker comes as white or transparent. It is suitable to print temporary outdoor signage but cannot withstand outdoor elements such as UV for the long term. It is also used for indoor signage and can be wiped with a damp cloth. The transparent sticker is ideally used on clear or plain white surfaces. Colourful surfaces will make your sign too busy or illegible. For custom cut stickers and other sticker options please visit optima.mt.

6. Colour Mode – Choose from Black Only, Full Colour or Mix. If duplex mode is selected Mixed option is not available since the back to back page sequence is disrupted when switching from black only to full colour mode. Once you choose Mixed mode the Mixed Printing Configuration is displayed so that you may choose the pages to be printed black only and the pages to be printed full colour. This printing configuration will ensure that no pages are left out from the document. Please refer to the opening points for full colour print quality.

7. Finishing Options

No Finishing – All printed papers will be left as loose sheets stacked in one pile with no shifting to seperate copies. If printing one copy and you require loose sheets then this option is fine. However if you are printing more than one copy of a document then we recommend choosing a different option.

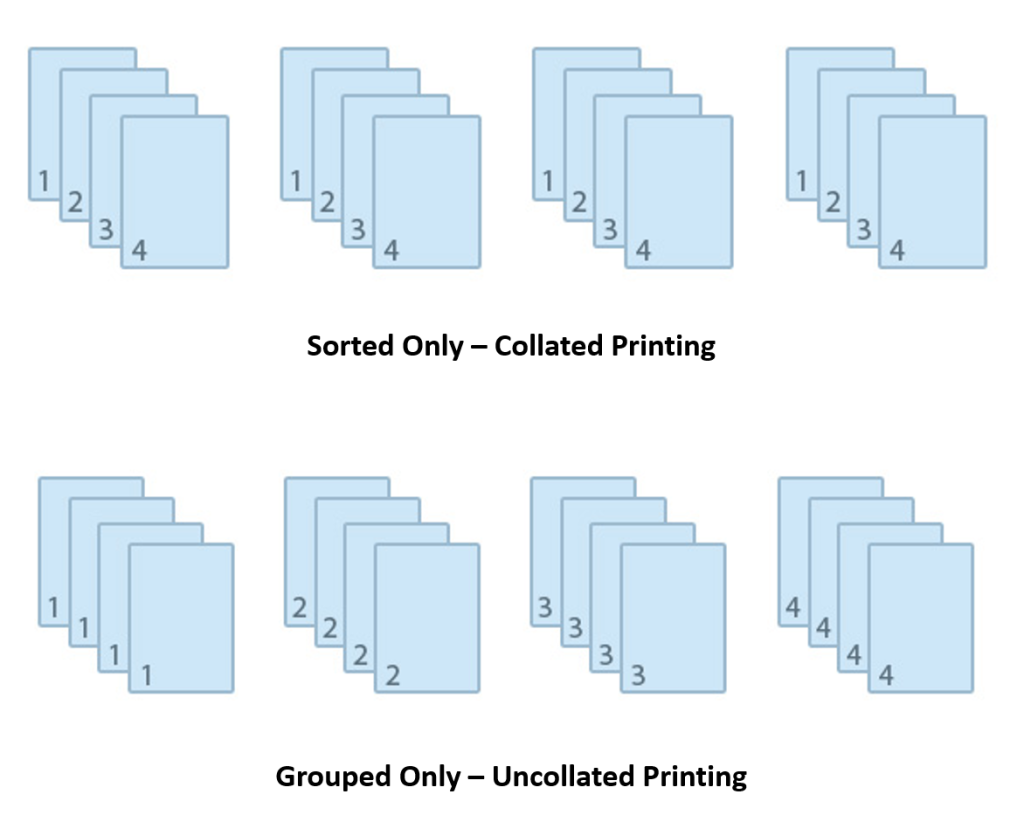

Sorted Only – also known as Collated Printing. This option is useful when printing more than one copy. The printed sheets will remain loose. Printing will be done in a manner where one copy of a multi-page document is printed from the first page to the last page, before the next copy is printed. For example – If you have a 10 page document to print 20 times for a class or team of 20 members, the printer will print the first copy from page 1 to 10 before moving to print the second copy from page 1 to 10 and so-forth up till the 20th copy. This is useful if the presenter would like to give the full set of notes to each student at once. Each set of notes is easily identifiable since a shift collate function is used to shift left or right different sets.

Grouped Only – also known as Uncollated Printing. The printed sheets will remain loose. The printed copies will be organised in a manner where the first page of a multi-page document is printed first for the number of copies required before the second page is printed for the number of copies required. For example – If you have a 5 page document to print 15 times for a class or team of 15 members, the printer will print the first page for 15 times before printing the second page for 15 times and so-forth up till the 5th pages is printed for 15 times. This is useful if the presenter would like to give all students page 1 only of the document before giving our the next page. Each set of notes is easily identifiable since a shift collate function is used to shift left or right different sets.

Stapled Top Left – The printed sheets are attached together with one metal staple on the top left corner. This is the most basic method to bind a set of sheets into one document. This stapling function can staple up to fifty 80gsm sheets: that is 50 page file if printed single sided and a 100 page file if printed duplex. This option is only available for 80gsm paper type.

Sorted and Punched / Grouped and Punched – The printed loose sheets will include a 2 hole punch, making it very convenient to immediately file in a 2 ring file. The hole punching is always done on the long edge of the paper. Please refer to the above explanation for the Sorted and Grouped option. The Punched option is only available for 80gsm paper type.

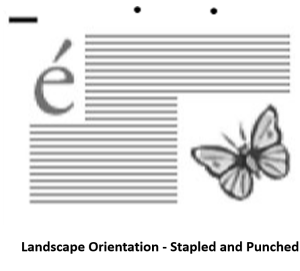

Stapled and Punched – The printed sheets are attached together with one metal staple on the top left corner and include a 2 hole punch, making it very convenient to immediately distribute and file in a 2 ring file. The hole punching is always done on the long edge of the paper. Caution must be taken when the document orientation is landscape and the double sided duplex mode option is selected. Depending on the content and the intended use, this option may not be suitable. Please refer to the above restrictions for the stapled and punched options.

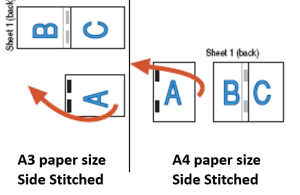

Side Stapled – also referred to as Side Stitched Booklets – The printed sheets are attached together with two metal staples on the left hand side. This option is a basic form of book binding that allows the user to flip pages from right to left. This form of book binding is frequently used for short term publications since it is cheap yet presentable and durable for short periods of use. In the case of A4 size sheets the side stapling is done on the long edge whereas A3 size sheets are side stitched from the short edge. The same restrictions apply as the Stapled Top Left option.

Plastic Comb Binding – This is a method of securing loose printed pages using a plastic strip with “teeth” that fits into rectangular holes in the paper. The rigid plastic strip forms the booklet spine and would resemble a hair comb when opened hence the name of this binding. This is the most common type of binding mainly because it is done on demand and is mostly known amongst the general users.

This type of binding comes with a plastic transparent cover sheet and a black cardboard back cover that matches the black spine.

Advantages: A comb binding booklet can open flat side by side on a flat surface making it very easy to read and write on both sides of the sheet. Pages will remain open flat with no resistance unlike the traditional glued reading book. Due to the availability of thick spines, plastic comb binding can take up a relatively large amount of sheets compared to other binding methods. A unique advantage of comb binding over other binding methods is that the spine can be opened any time to add or replace pages

Disadvantages: Comb binding isn’t particularly known for its long term durability, so you will want to consider how your documents will be used before deciding whether or not comb binding is the right choice for your project.

Recommended Use: It is perfect for presentation of assignments and reports and as workbooks for a short period (one school term) but not recommended as workbooks to be used throughout an entire scholastic year. It is also the best option if the document is not final and may require replacement of pages and insertion of additional pages.

Booklet Thickness: Comb binding spines can take from as little as 10 sheets up to 450 80gsm sheets. This means that if printed double sided it can hold a document of up to 900 pages. Using thicker paper will reduce the number of sheets capacity accordingly. Our printing application will not show the binding option if the number of pages exceeds the maximum spine thickness.

Coil Binding – This is a method of securing loose printed pages using high quality PVC plastic coil that resembles a long spring. The coil is inserted and twisted through small holes punched along the spinal edge of the pages. This type of binding is increasing in popularity for a number of good reasons and is today a popular binding method for ready made notebooks and notepads.

This type of binding comes with a plastic transparent cover sheet and a black cardboard back cover that matches the black PVC coil.

Advantages: A coil binding booklet can open flat side by side on a flat surface making it very easy to read and write on both sides of the sheet. Pages will remain open flat with no resistance unlike the traditional glued reading book. A further advantage of coil binding over other binding methods is that pages can rotate a full 360 degrees around the spine, fold all the way back upon itself and yet still remain flat, allowing easy reference from one page to another while taking up minimal room on a desk or table. It is also much more durable than other binding methods and the PVC will not break if twisted or bent.

Disadvantages: There are no significant disadvantages to note except that we do not offer the same page capacity as plastic comb binding. However as the popularity of this binding method increases we will provide for a higher volume of sheets. Coil Binding like most other binding options cannot be opened to add or replace pages. The spine will need to be replaced.

Recommended Use: Being durable and safe, coil binding is our recommended binding option for schools, child care centres and training institutions where documents will be used over a long period of time and multiple times.

Booklet Thickness: Coil spines can bind from as little as 10 sheets up to 160 80gsm sheets. This means that if printed double sided it can hold a document of up to 320 pages. Using thicker paper will reduce the number of sheets capacity accordingly. Our printing application will not show the binding option if the number of pages exceeds the maximum spine thickness.

Wire Binding – This is a method of securing loose printed pages using a metal C-shaped wire spine that is threaded through the holes of a document and then squeezed closed to form an ‘O’ shape keeping the document pages firmly in place. This type of binding is still popular although other binding options may be more suitable for certain projects.

This type of binding comes with a plastic transparent cover sheet and a white cardboard back cover that matches the white wire spine.

Advantages: A wire binding booklet can open flat side by side on a flat surface making it very easy to read and write on both sides of the sheet. Pages will remain open flat with no resistance unlike the traditional glued reading book. Wire binding allows pages to rotate a full 360 degrees around the spine although it is not as practical as coil binding.

Disadvantages: The wire is relatively rigid and if not handled with care will loose shape and pages may come loose. Since the binding material is metal wire it is not safe for young students and can be dangerous. Once closed wire binding cannot be opened to add or replace pages. Replacing the spine without damaging the document pages is not an easy task.

Recommended Use: Wire binding gives a more rich and professional look to a document since the material is metal as opposed to plastic or PVC. We recommend wire binding for business and professional reports, presentations, brochures and notebooks handled by adults in a ‘handle with care’ environment.

Booklet Thickness: Wire spines can bind from as little as 10 sheets up to 250 80gsm sheets. This means that if printed double sided it can hold a document of up to 500 pages. Using thicker paper will reduce the number of sheets capacity accordingly. Our printing application will not show the binding option if the number of pages exceeds the maximum spine thickness.

Transparent Cover Book Binding – This option is the traditional book binding method of using glue to bind the interior pages and the cover together. This method of binding is also known as perfect binding

This type of binding uses a pre-fabricated book cover made up of a plastic transparent front cover and a black 180gsm cardboard for the spine and back cover.

Advantages: A very neat, economical and easy way to bind documents into a book without the need to design the book cover. Pages are glued together to form a hard spine making it a durable and presentable book option.

Disadvantages: The book cannot be opened flat and keeping the book open to write on the pages may not be easy. Using it as a workbook to read and write may present challenges to students. Once glued no pages can be added or replaced.

Recommended Use: This binding is suitable to bind study books, training manuals, reports and yearbooks used for reading and reference purposes and also to archive neatly on shelves.

Booklet Thickness: This binding is suitable for 25 sheets up to 325 80gsm sheets. This means that if printed double sided it can hold a document of up to 650 pages. Using thicker paper will reduce the number of sheets capacity accordingly. Our printing application will not show the binding option if the number of pages exceeds the maximum spine thickness.

Soft Cover Book Binding – This option is the traditional book binding method of using glue to bind the interior pages and the cover together. This method of binding is also known as perfect binding

This type of binding allows the customer to have a fully customised book. The front cover page, the spine, the back cover and the inner pages are all user defined. The cover is printed on 350gsm premium white uncoated card stock.

The artwork for the cover may be done in two ways: The simplest form is to include the front cover artwork as page 1 and the back cover artwork as the last page of the PDF document. If you wish to include text on the spine this may be added as an order note. Alternatively one may create the cover artwork on a separate pdf document and email the file to [email protected], making reference to the order number. It is important that on checkout, an order note is included to notify us that the cover will be sent by email.

Advantages: Perfect-bound books have a professional appearance and aesthetic appeal. Pages are glued together to form hard spine making it durable and nice to stack on a book shelf.

Disadvantages: The book cannot be opened flat and keeping the book open to write on the pages may not be easy. Using it as a workbook to read and write may present challenges to students. Once glued no pages can be added or replaced.

Recommended Use: This binding is suitable to bind reading books, memory books and other private collections that will last and hold memories for many years.

Booklet Thickness: This binding is suitable for 25 sheets up to 325 80gsm sheets. This means that if printed double sided it can hold a document of up to 650 pages. Using thicker paper will reduce the number of sheets capacity accordingly. Our printing application will not show the binding option if the number of pages exceeds the maximum spine thickness.

Gloss Lamination or Matte Lamination – This option is used to seal paper prints in plastic. The process involves placing the paper print in a plastic pouch and passing the plastic pouch through the lamination machine. The lamination machine has heated rollers that will melt the adhesive on the plastic pouch to create a sealed plastic document. We offer gloss lamination and matte lamination.

We do not recommend cutting the laminated document. Once the lamination is cut, the edge of the document will be exposed to the environment and the lamination film may detach from the paper.

Advantages: A great way to protect a paper document from spills, tears, and wrinkling, making it almost indestructible in day to day use. Using a gloss lamination improves the visual appearance of the print, producing a shiny, glass-like appearance that enhances the colour and vibrancy of the ink. A matte lamination produces an elegant, deep and sophisticated finish to the print.

Disadvantages: Laminated documents create a sturdy edge to the document which may be too hard for young children. When using lamination one looses the soft warm touch of paper. The gloss lamination can create a glare that makes it difficult to read the contents on the document.

Recommended Use: An economical option to create outdoor signage or hard wearing signage. Training sheets and information sheets in constant use in industrial and outdoor environments are ideally laminated. Basic menu printing can also be laminated so as to avoid tearing and can be wiped. Higher quality laminating options can be found at optima.mt.

Fold Only or Crease and Fold – This option is used to fold the A3 size paper in half to create an A4 size document or to fold an A4 size paper to create an A5 document. The Fold Only option is available for 80gsm up to 135gsm paper.

Thicker paper also referred to as card stock will not fold easily and neatly if not creased before folding. The aim of the crease is to ‘score the card’ (create a folding mark along the card). This will create an easy and neat fold.